Our Products & Services

Explore Our Sustainable Products

Zerund PP

Annually, 250 billion bricks are used in India, emitting 42.64 MT of CO2 per Red Brick industry. To combat this issue, we have developed our eco-friendly, lightweight, cost-effective, and crack-resistant bricks, composed of 70% waste materials such as fly ash and plastic waste.

Parameters

Value

General Size

600 mm*200 mm*(75-300)mm

Thickness

75, 100, 125, 150, 200, 225

Compressive Strength

45 to 55 kg/cm3

Dry Density

551-900 kg/m3

Water Absorption

6-7%

Thermal Conductivity

.24W/m-k

Drying Shrinkage

.16%

Zerund PP Brick Features

Cost saving

Buildings made from our bricks can save upto 15-20% money in comparison to normal red bricks.

Higher strength

Very high compressive strength than other lightweight bricks.

Lightweight

50% Lighter than normal red bricks.

Less Water Absorption

One of the best properties that differentiates our product from our competitors is the less water absorption. It helps to minimise cracks and emorescence.

Fire resistance

Our reports prove that the product has 1.4 times more fire resistance than normal red clay brick.

Energy saving

One of the best properties that differentiates our product from our competitors is the less water absorption. It helps to minimise cracks and emorescence.

Sound insulation

Our products can be used extensively at places requiring high sound insulation like Auditoriums, move halls, hospitals etc. This is because the bricks have air voids within them which creates a lot of sound insulation.

Time saving in construction

The bricks are easy to handle and saves a lot of time during its installation High tensile strength: The use of plastic helps to increase the tensile properties of the brick this as a result helps to reduce cracks in the product.

Zerund Certifications:

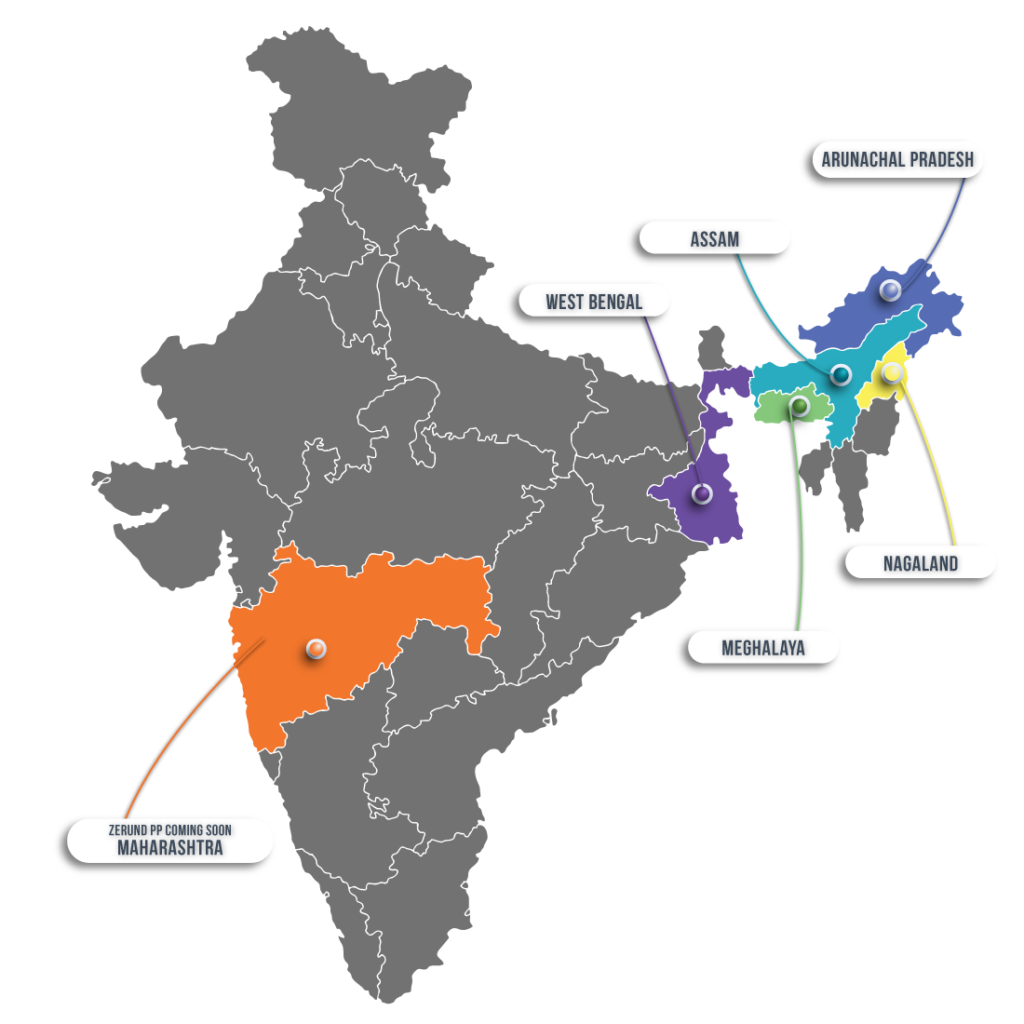

Markets we’re in

Zerund NP

We also deal in non-plastic-based autoclaved lightweight bricks with high strength, good insulation, and cost-saving properties

Available in Maharashtra, India

Product Specifications:

Block Specifications

Parameters

Specifications

General Sizee

600 mm*200 mm*(75-300)mm

Thickness

75, 100, 125, 150, 200, 225

Minimum Compressive Strength

3 to 4.5 N/mm2 (IS 2185)

Minimum Dry Density

450 to 650 kg/m3

Thermal Resistance

0.8-1.25 per inch of thickness

Fire Resistance

4* Hours

Thermal Conductivity

0.16 to 0.18 W.Mk

BHARAT BOND ADHESIVE

Bharat Bond Adhesive is a ready-to-use, grey-cement-based, non-shrink, self-curing mortar designed to fix Zerund blocks. Only water needs to be added to use it. This thin jointing material has very high tensile adhesion strength, which improves the overall masonry strength.

Product Specifications

Parameters

Specifications

Appearance

Grey Powder

Water Required

35%

Pot Life

~1.5 - 2 hrs

Curing

Not required

Tensile Adhesive Strength

>0.41 MPa (as per ASTM - C1660)

Coverage

170 - 180 sq.ft (for 4" thick blocks)

ZERUND PREMIX

We are developing Zerund Premix, which can be a milestone in polymer technology. It will help lightweight brick manufacturers reduce raw material usage and significantly reduce the amount of water required in the process. This, in turn, develops high compressive strength and reduces water absorption in the finished product. Zerund Premix admixture will also contribute to reducing the carbon footprint, thus aiding in the creation of a greener product.

Product Specifications

Parameters

Specifications

Physical Appearance

Liquid

Colour

Light Pink

Dry Material Content, % by Mass

21 +/- 3

Specific Gravity(27 deg C+/- deg C)

1.050 +/-0.02

PH

Min 6.0

SERVICES

Expert Training and Support for Masons and Contractors

Mason Meet is organised by the dealer and the manufacturer at place convenient to the Mason as well as the dealer. This is where the masons are told about the company, it’s promoter the manufacturing process any new technology that is being incorporated etc. Further the masons are given a live demo session on using the product, what precautions are required.

What tools are used and how it is used, so that it is efficient, cost and time is also saved. In the end a small Q&A session is held with the masons and if they have any doubts it is cleared. In the end lunch/ dinner / tea and snacks are served followed by distribution of gifts to the masons.

The benefits of having Mason meets are that they are in close contact with the end consumers; they can always give an advice to the clients and clear their doubts. It also is an act of word of mouth publicity where physical advertisement is not possible.

After Sales Service

- Visit sites to ensure that customers receive better quality of product.

- Give demonstration at site for proper masonry work.

- Solve complaint if any arise from the customer.

- Periodical site visit to look after the masonry work.

Calculate the number of bricks you need for your project based on the area with ease.

Zerund Bricks Features

India produces 9.5 million tonnes of plastic annually, and Zerund currently uses 1500+ tonnes of plastic waste and 30,000 tonnes of fly ash (industrial waste) annually in its plants. In India annually, 42.64 MT of CO2 is emitted by each red brick industry, whereas Zerund is a carbon-negative product and has net emissions of -.44 kg CO2 per kg of brick. Energy consumption in the manufacturing of Zerund bricks is 0.013 KWH/kg, which is 61 times less compared to red bricks, and no fertile agricultural soil is used in the manufacturing of Zerund bricks.

We are setting up a state-of-the art R&D centre to further develop newer technologies in sustainable construction materials and also to utilise other industrial waste in large volumes.

GUIDANCE TO MASONS

We provide free installation guidance to the masons at the construction sites.

FREE CONSULTANCY

We provide free consultancy about the structure, especially on the brick walls.

QUANTITATIVE ESTIMATION

We provide quantitative estimation guidance to the customers.

QUALITY CONTROL

Our executives regularly visits sites for quality control management